MELANGE

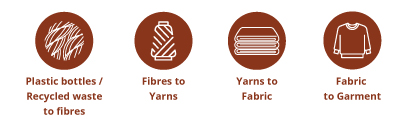

Our vertically integrated infrastructure enables us to

produce high-quality melange yarn in a combination of

various raw and dyed fibers. we practice an ethical and

eco-conscious manufacturing process that uses recycled

resources and minimal water

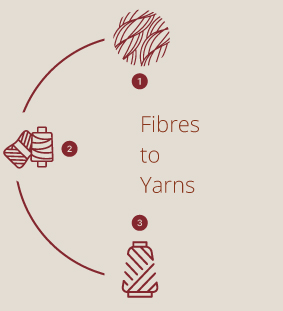

MELANGE YARN PRODUCTION

We go through various stages to get the preferred

products. The stages involved in the making of the

melange yarn are –

- Mixing

- Fibre cleaning

- Carding

- Combing

- Drawing

- Roving

- Spinning

- Winding