INFRASTRUCTURE & PROCESS

INFRASTRUCTURE

&

PROCESS

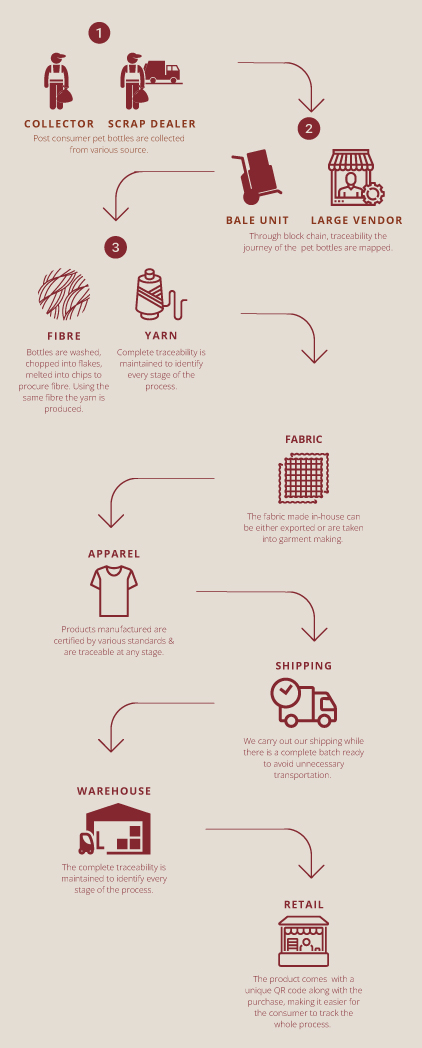

VERTICALLY INTEGRATED OPERATIONS

Based on the foundation of vertically integrated infrastructure, we have good control over our supply chain

and processes right from recycling Pet bottles into yarns, to recycling the post-industrial waste along with

our knitting unit and garment manufacturing division.

Better

lead time

Lesser

transportation

cost

Better

quality

Traceable

process

Transparent

supply chain

Better

lead time

Lesser

transportation

cost

Better

quality

Traceable

process

Transparent

supply chain

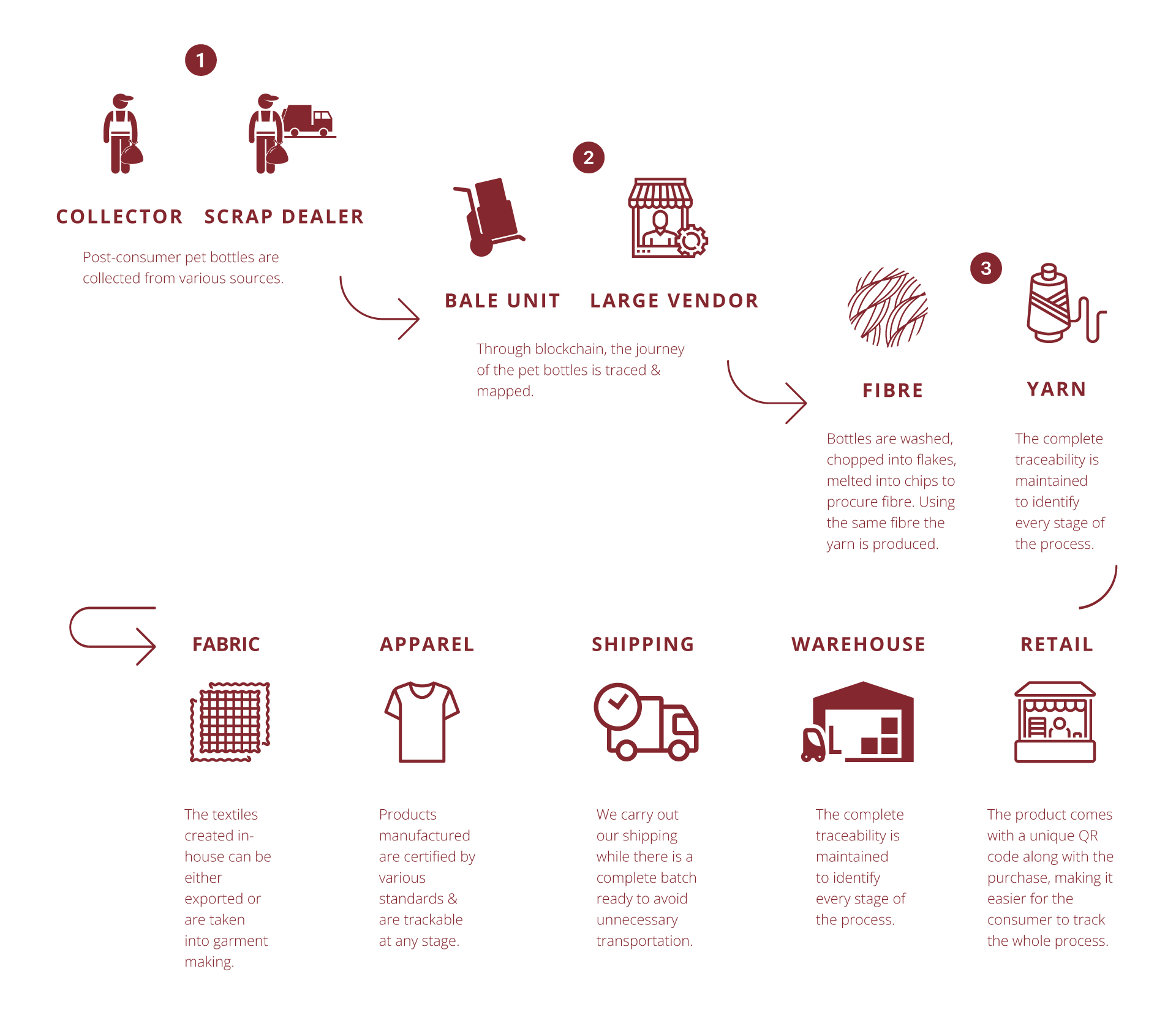

PROCESS FLOW OF RPSF

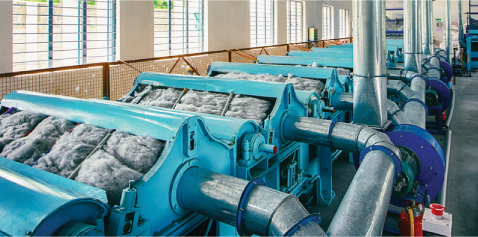

We collect 8 million PET bottles and convert them into 140 tons of RPSF every day using

our vertically integrated RPSF plant

PROCESS FLOW OF RPSF

DOPE DYEING

We carry out our dyeing process keeping the

environmental impact in mind, effectively using

almost zero percentage of water in the process.

We are the first company worldwide to

receive an LCA report on dope dyeing for

the RPSF process.

Lesser environmental pollution

Reduced process

& time

Saves 90%

water

DOPE DYEING

We carry out our dyeing process keeping the

environmental impact in mind, effectively using

almost zero percentage of water in the process.

We are the first company worldwide to

receive an LCA report on dope dyeing for

the RPSF process.

Lesser

pollution

Reduced process

& time

Saves 90%

water

OUR INFRASTRUCTURE

1,60,000

Spindles 80 tons of

melange & raw yarn / day

melange & raw yarn / day

29

Windmills – 30 MW per year

72 MW

Renewable energy solar +

windmill 72M KWH per year

windmill 72M KWH per year

8 Million

Recycle PET bottles every

day, 140 Tons RPSF/ day

day, 140 Tons RPSF/ day

20 Tons

In-house knitting machine with a

knitting capacity of 20 tons per

day

3.5-500K

600 state of the art machinery

with 3.5-500k Garments

production per month

CIRCULARITY

We give waste a new life. Every day.

Ecoespin turns textile waste from post-industrial and

post-consumer origins into high-quality recycled cotton

fiber and fiber blends. We work together with our

partners to integrate our process into the supply chain,

providing a closed-loop end-to-end solution.

CIRCULARITY

We give waste a new life. Every day.

We make sustainable fabric from a closed-loop process, where raw materials are used again to reduce the use

of virgin resources and the amount of waste generated in the first place.

of virgin resources and the amount of waste generated in the first place.

Ecoespin turns textile waste from post-industrial and post-consumer origins into high-quality recycled cotton

fiber and fiber blends. We work together with our partners to integrate our process into the supply chain,

providing a closed-loop end-to-end solution

fiber and fiber blends. We work together with our partners to integrate our process into the supply chain,

providing a closed-loop end-to-end solution

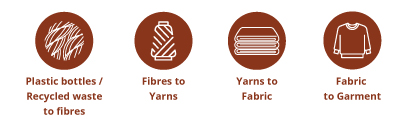

OUR OFFERINGS TO YOU

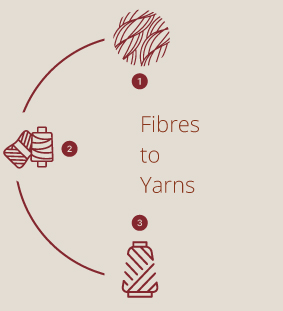

We develop fibre using recycled materials, from pet

bottles or Post-industrial waste that create yarns, and

fabrics using our in-house machinery. We also support

brands by offering a completely sustainable

garment range.

Our vertically integrated operations enable us to offer you sustainable solutions, at any stage of product development. We

develop fibre using recycled materials, from pet bottles or Post-industrial waste. Our innovative blends of fibres that create

yarns, in turn, help produce fabrics using our in-house machinery. We also support brands by offering a completely

developed garment range using sustainability as a core concept.